The success or failure of your shed relies greatly upon its foundation. Even the best-designed, strongest-built sheds won’t last very long if set upon a weak or poorly constructed base. Therefore, building a strong, durable foundation is arguably the most critical step in building your shed. Let’s take a look at the best foundation options for your shed.

On-Grade vs. Frost-Proof

There are several different types of shed foundations, but they can be divided into just two categories: on-grade and frost-proof.

On-Grade Foundations

Another name for an on-grade foundation is a floating foundation. This type sits directly on the ground. One of their benefits is that they are quick and easy to build. It is not necessary to dig any holes or pour concrete for this foundation type. On-grade foundations are sufficient for most small to medium-size sheds.

Frost-Proof Foundations

Frost-proof foundations present more building challenges than on-grade types, but they’re much stronger and longer-lasting. For that reason, frost-proof foundations are often called permanent foundations. While this type of foundation can be built virtually anywhere, it works well in areas where the weather is colder and that experience frost heave. Frost-proof foundations are usually made by pouring concrete footings, piers, or a monolithic slab. But you can also create one with pole-barn construction, which uses a series of tall round poles or square posts set into deep holes. Frost-proof foundations are ideal—and often code required—for larger sheds.

On-Grade Foundations

An on-grade foundation is one that sits on the ground. It is not a permanent shed foundation. Therefore, it can be moved if needed. It can be a solid-concrete block, skid, or timber-frame foundation. You would choose one of these if you have a small to medium-sized shed, if you may want to move your shed at some point or if you cannot dig into the ground.

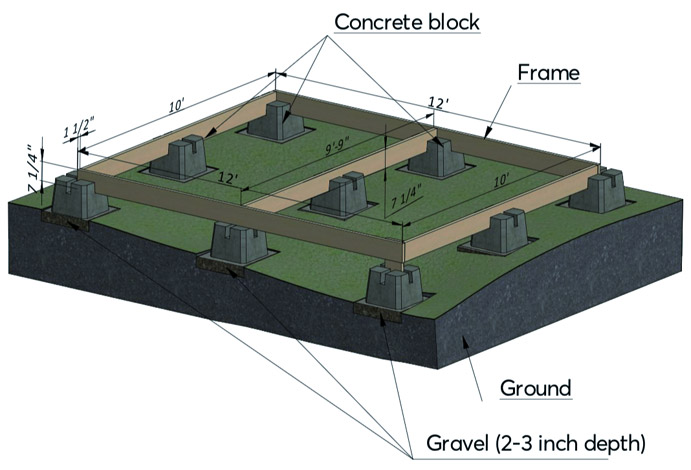

Concrete Block

A series of solid-concrete blocks are used to build this type of foundation. They should be laid out in straight rows, evenly spaced from each other. The size of your shed and the lumber being used for the floor joists will determine how many blocks you need and how much space will be between them.

Important: Do not use hollow wall blocks. Over time, they can crack and crumble due to the weight of your shed.

The blocks most commonly used for on-grade foundations measure 4-inch thick x 8-inch wide x 16 inches long. There are also 2-inch-thick blocks, called patio blocks, which can be set on top of the thicker blocks when it’s necessary to raise one block even with the others.

Tip: Please remove the grass under each solid-concrete block to prevent soil erosion. We recommend using 2-3” of gravel to cover the dirt. Use a hand tamper to compact the gravel and then place the block on top of it.

Skid Foundation

Skid foundations have been used to support sheds and other outdoor buildings for more than 300 years. Building this type of on-grade foundation is very easy. Using two or more long, straight skids (timbers), lay them on the ground parallel to each other and evenly spaced apart. Build the shed’s floor frame on top of them.

A skid foundation takes very little time to build, and it is one of the easiest options. One of their benefits is the fact that they distribute the building’s weight evenly over a wide surface. But they are best used at sites that are quite flat. Typically, skids are made from pressure-treated 4x6s, 6x6s and 8x8s. Size can vary depending on the size of the shed you are building.

Tip: If long, straight timbers are not available, the skids can be made by gang-nailing 3-4 pressure-treated 2x6s or 2x8s. Once nailed together, they should be set on edge.

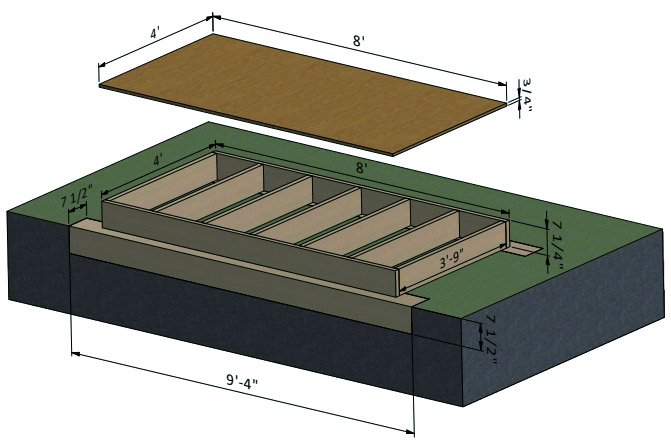

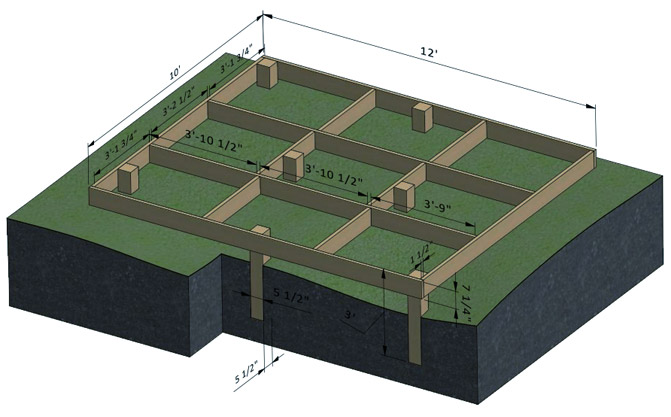

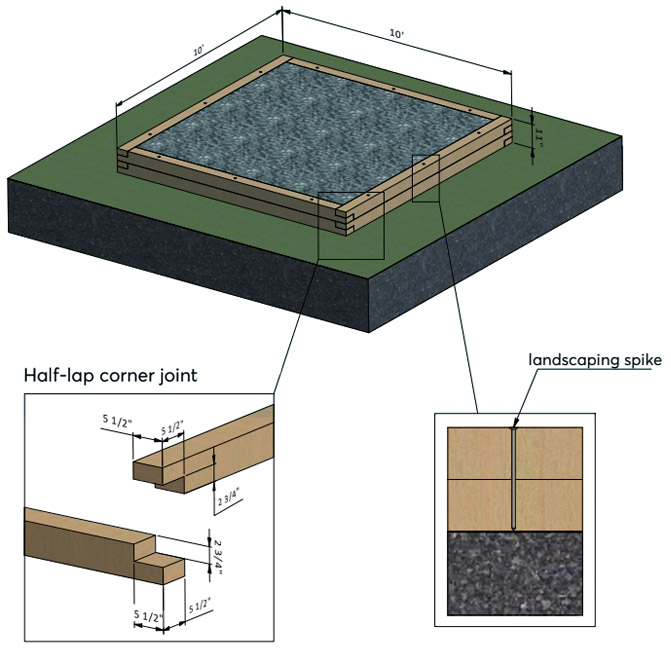

Timber-Frame

A timber-frame foundation is made by constructing a rectangular, wood frame and positioning it on top of a bed of gravel. It is very easy to build. The shed walls are then built on top of the frame. One reason timber-frame foundations are so popular is that it accepts a variety of flooring options. For example, the floor space within the frame can be filled with bricks, concrete, gravel, marble chips, or bluestone slabs. You can also simply screw down pressure-treated decking. Pressure-treated 4x4s, 4x6s, or 6x6s are typically used to make timber frames. Half-lap corner joints are used to join the timbers together, or they can also be stacked two or three timbers high and fastened together. Structural screws or long landscaping spikes can work well for that.

Alternatively, 2×8 boards can be used, both for the outer contour and for the inner joists. Note that the short internal joists are staggered to facilitate installation.

If the site is not pre-leveled, you can use supports made of 6×6 timber and an average length of 3 feet (depending on the slope of the relief that needs to be compensated)

Tip: To ensure the timbers don’t rot prematurely, be certain to use pressure-treated lumber that’s rated for ground-contact use.

Frost-Proof Foundations

Frost-proof foundations are able to support more weight than on-grade foundations, which is why they are often chosen. They are permanent, and building one involves several additional steps. You must dig below the frost line and use concrete and piers to maintain the foundation’s structural integrity. This type of foundation will not shift. Some examples of this type include pole-barn, concrete pier, and poured concrete slab foundations. This option is highly beneficial for colder areas where freezing temperatures could cause damage to a shed’s foundation.

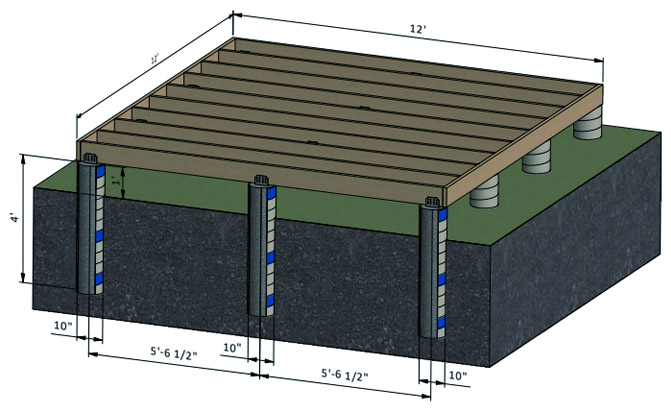

Concrete Piers

A concrete pier foundation is simply a column of concrete poured into a hole in the ground. If you are building your shed in a cold-weather region, make sure the holes extend below the frost line. This can prevent the adverse effects of frost heave from having an impact on your shed. Two or more rows of piers support the shed’s floor frame. If you need to extend the height of the pier above the ground, line the holes with fiber-form tubes, which are commonly known by the trade name Sonotube, and then fill the tubes with concrete. The shed’s floor frame can be secured to the concrete piers with galvanized-metal hardware, such as post anchors or beam connectors. Just be sure to set the hardware into the piers before the concrete hardens.

Tip: Frost-proof foundations are typically required by code for sheds larger than 200 sq. ft. or taller than 12 ft. However, building codes differ from state to state, so be sure to check with the local building department for the exact requirements in your area.

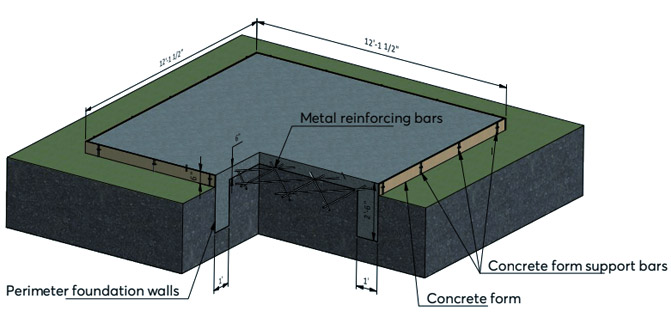

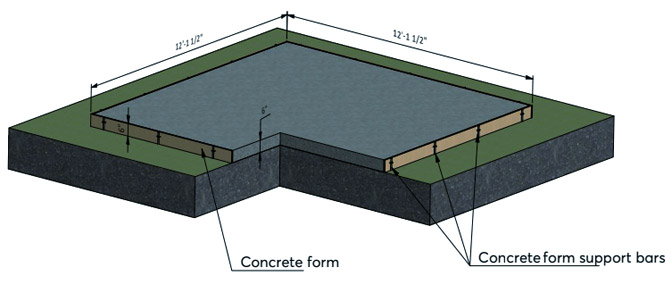

Poured-Concrete Slab

A poured-concrete foundation is the best choice for larger outbuildings that will be used to store heavy equipment, such as woodworking machines, tractors, boats, motorcycles, snowmobiles, and cars. There are two basic ways to pour a concrete slab, but only one qualifies as a frost-proof foundation. It’s called a monolithic slab, and the shed floor and the perimeter foundation walls are all poured at the same time. The walls extend down to the frost line and are usually about 8 to 12 inches thick. The floor is only 4 to 6 inches thick, but it’s reinforced with wire mesh or metal reinforcing bars.

The second type of concrete floor is known as a floating slab or an on-grade slab. It’s simply a 4 to a 6-inch thick layer of concrete that sits right on the ground. This type of shed floor should never be used when the building codes call for a frost-proof foundation.

Pole-Barn

All of the previously mentioned foundations are designed to support the shed’s floor frame. The floor frame, in turn, then supports the walls. A pole-barn foundation is completely different: it technically doesn’t even have a floor.

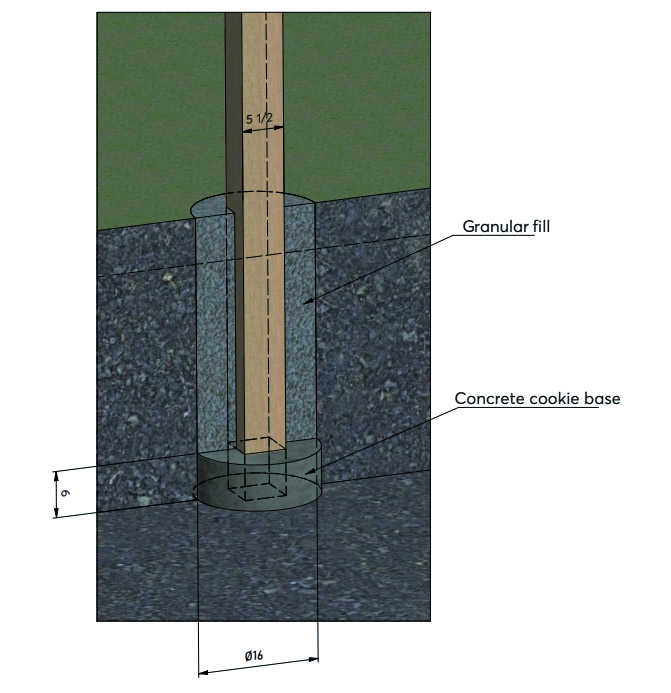

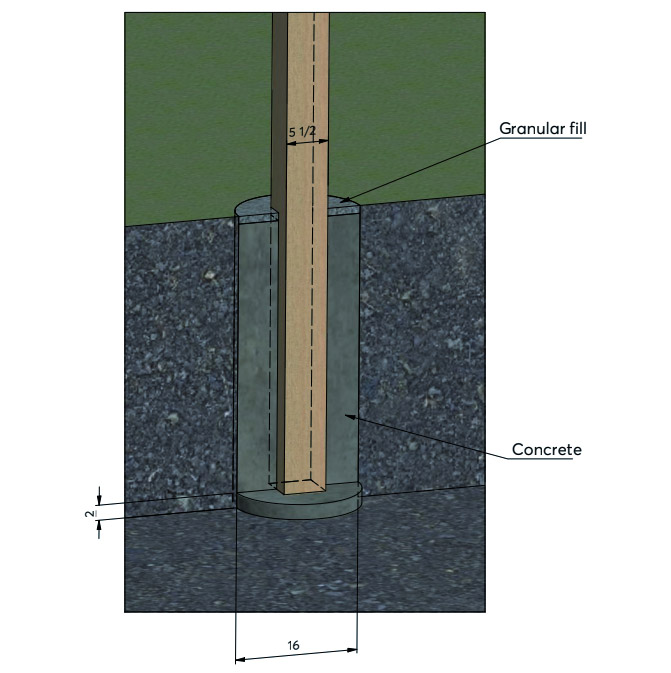

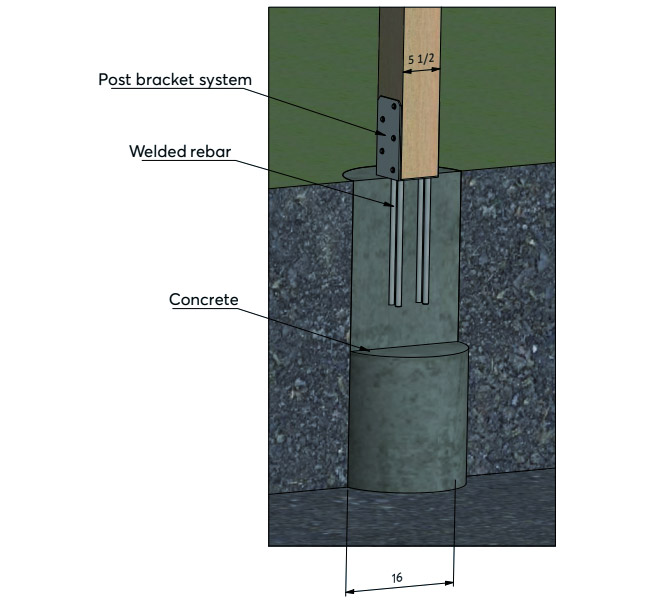

Pole-barn construction consists of several holes dug below the frost line around the perimeter of the foundation. Concrete footings are poured into each hole, and tall round poles or square timbers are set into the holes. Horizontal beams are fastened across the poles and then the walls are secured to the beams. The bare ground within the pole-barn foundation can be covered with processed stone, pea gravel, or wood chips. Or, you could pour a concrete floor.

One of the options is to use a pre-formed concrete cookie pad, it should be 6 inches thick and 12-16 inches in diameter. Place the concrete pad in the prepared pit and place the pressure-treated lumber in the opening. The pit itself can be filled with gravel or other medium-fraction bulk materials, which will act as drainage and remove moisture from the lumber.

The next way is to concrete the entire post. Depending on the region in which the construction takes place, additional processing against rotting of the part of the pillar located in the concrete may be required. While the concrete hardens, it is necessary to fix the timber, having previously leveled it in a vertical position using a building level.

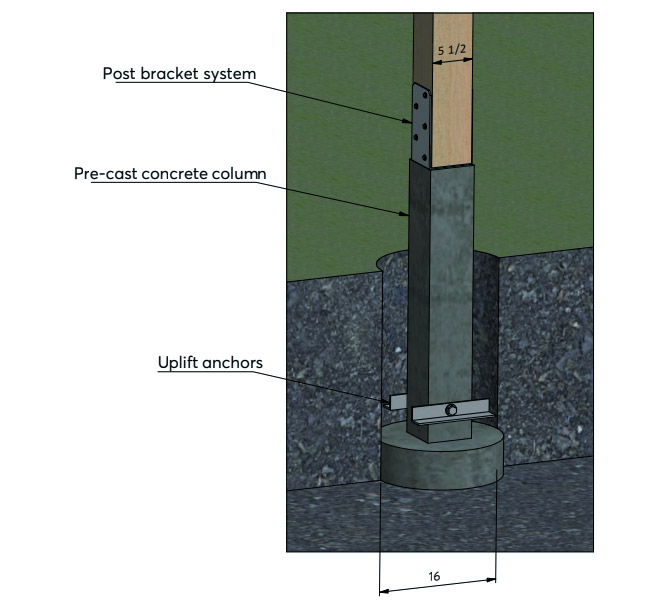

The third method involves the use of post-base, the installation fittings of which are installed in not yet hardened concrete, which gave the name itself. After hardening, the pressure-treated lumber is installed in the post-base using the appropriate fasteners.

And finally, the last method, which raises the post as much as possible above the ground, and thus best of all protects it from decay, is the use of perm columns. A ready-made concrete block with a column is lowered into the prepared pit, on which the pressure-treated lumber is installed using a post base. The pit can be filled up with anything as concrete does not need drainage.

Tip: Since the floor of a pole barn is nearly flush with the surrounding grade, it provides easy access for lawn tractors, boat trailers, farm machinery, and livestock.

Additional Types of Foundations to Consider

When it comes to building a shed foundation, you have a lot of options to choose from. Here are a few more options you might want to consider.

Adjustable Plastic Base

Smaller sheds may not need much of a foundation; especially if the current landscaping can support it well. Plastic shed jacks can be used to ensure that the foundation is firm and level.

Pros:

- It will be very quick and easy to install

- Leveling can be done quickly

- The shed will be very close to the land level

- This is a great option for both small and large sheds

Cons:

- There is the possibility of sinking over time

- This type of foundation material is not available everywhere

- This may not be the best choice if the ground is sloped

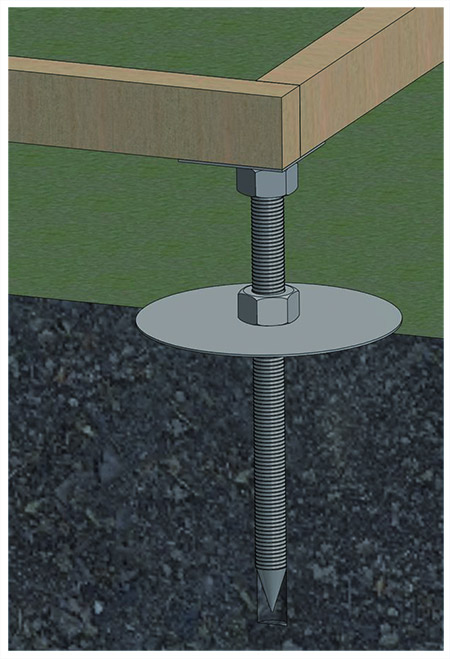

Adjustable Metal Base

Metal shed jacks work the same way, but they may be more appropriate, depending on what the shed is being built on. They work well when the ground has a slope and needs to be made level.

Pros:

- It is relatively inexpensive

- It is easy to install

- They can be moved up and down with just some basic tools

Cons:

- It’s important to use a lot of care to make sure the foundation can support the load of the shed and everything inside

- It will be harder to move the shed if it needs to be relocated

- You will need to have people helping you to ensure it gets installed correctly

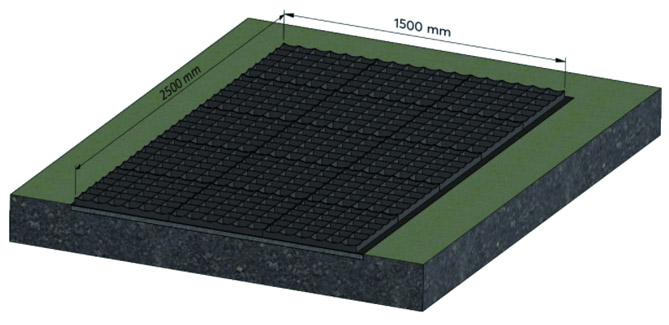

Plastic Grid Foundation System

There are some plastic grid systems that are specifically designed to be used as shed foundations. They can be a great alternative to using concrete slabs. Plastic is lightweight and so the grids are very easy to handle. An ordinary hand saw can cut and shape them, and their air cells will keep the shed dry.

Pros:

- Plastic is a great option for a light-duty shed because it will have a more natural feel

- Plastic will drain water away naturally

- Plastic is UV resistant

- This type of shed foundation is very easy for people to install themselves

- Relocation is very easy

Cons:

- This type of foundation is prone to rot and may not last as long as you would hope

- Plastic is very lightweight, which could mean that it might move easily

- The shed will need to be secured so that it cannot move

There are some plastic grid systems that are specifically designed to be used as shed foundations. They can be a great alternative to using concrete slabs. Plastic is lightweight and so the grids are very easy to handle. An ordinary handsaw can cut and shape them, and their air cells will keep the shed dry.

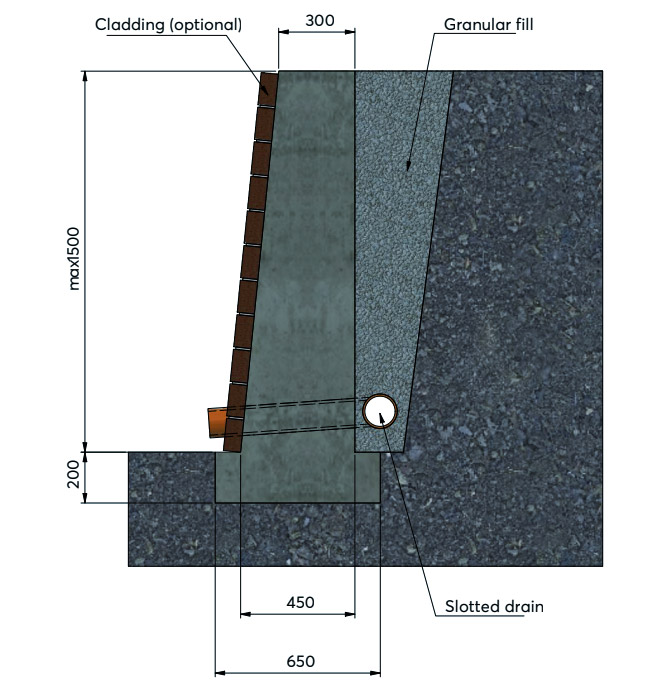

Retaining Wall Type Base

Finally, if erosion is a concern for you around the area you intend to build your shed, you may want to consider a retaining wall-type base foundation. This takes a little more work, of course. But the benefits may be well worth it.

Pros:

- Depending on the material being used, the foundation will likely be very durable

- This type of shed foundation is usually a very attractive option

- Depending on the material being used, this type of foundation is likely to stand up well to all kinds of weather

Cons:

- The foundation could break and need to be repaired

- This type of foundation is likely to be more expensive to build

- Extra care must be taken concerning proper support and drainage

Shed Foundation Comparison

Every shed foundation type has its advantages and disadvantages. Choosing the right shed type for you really depends on a few different factors:

- What type of shed you are building.

- The landscaping of the area you are working in.

- What the weather tends to be like in your area.

The following table can be a helpful guide as you make your decision.

| Shed Type | Economical | Easy to Move | Water Proof | Good for Slopes | Great Support | Suitable for Cars |

| Adjustable Plastic Base | ✓ | ✓ | ✓ | ✓ | ✓ | |

| Adjustable Metal Base | ✓ | ✓ | ✓ | ✓ | ||

| Plastic | ✓ | ✓ | ✓ | ✓ | ||

| Timber | ✓ | |||||

| Concrete Paving Slabs | ✓ | ✓ | ||||

| Poured Concrete Base | ✓ | ✓ | ||||

| Pier Foundation | ✓ | ✓ | ✓ | |||

| Retaining Wall Type Base | ✓ | ✓ |

Start Working on Your Shed Foundation Today

Now that you know which shed foundation is right for you, learn how to build a shed floor. We hope that the information we have shared with you today has been helpful.

Joseph Truini is a host on the Today’s Homeowner TV show and co-hosts the weekly Today’s Homeowner Radio Show. He has written three best-selling shed-building books and lives in Roxbury, Connecticut.

Joseph Truini is a host on the Today’s Homeowner TV show and co-hosts the weekly Today’s Homeowner Radio Show. He has written three best-selling shed-building books and lives in Roxbury, Connecticut.

Hi Joseph, I want to build a shed foundation for a pre-fab 6′ x 8′ shed for garden tool storage that will deter rats and other animals from burrowing underneath. Do I need to pour concrete or do you think gravel would be sufficient?

Absolutely Great Read . Thank you

Building a 12×24 prefabricated shed best way to do footing they need to meet garage height 5’ from ground thank you

Where do you find those adjustments metal bases?

I Googled both “pre-formed concrete cookie base” & “pre-formed concrete cookie pad.” No results. The closest thing that came up was a concrete deck block at Home Depot. Where would I find the concrete base/pad referenced in this article under Pole-Barn?

Hello,

Thank you for this information. Really helpful.

Any thoughts on the metal galvenized base used by TuffShed? I’m considering buying that myself elsewhere and building the shed myself. I’ve a 12×14 concrete foundation that will sit on.